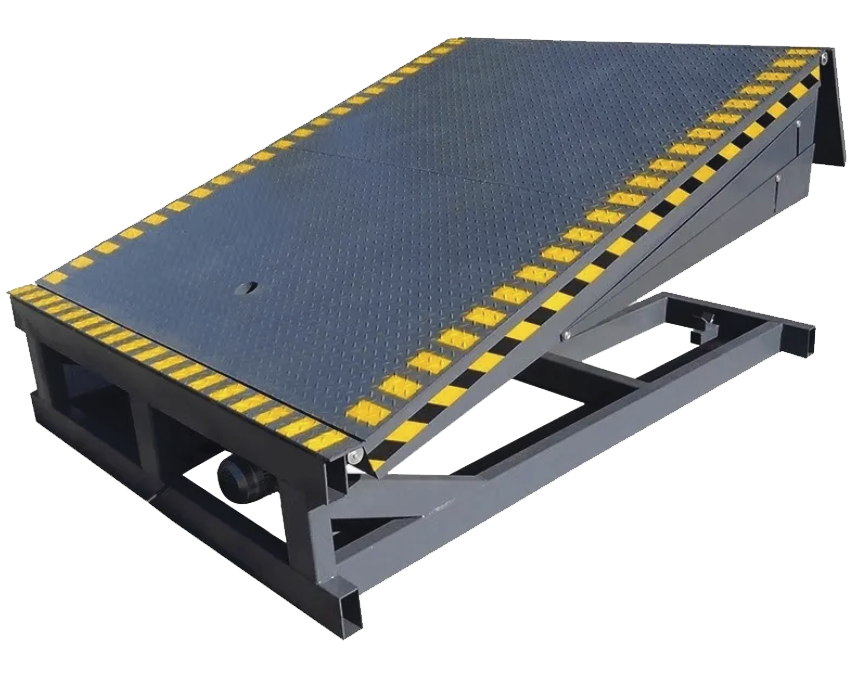

The yard ramp is a loading equipment that working in conjunction with forklifts, the ramp's height can be adjusted according to the vehicle floor's height. With it, the forklifts can be driven into the inner of the vehicle to handle cargo directly. Only with one operator, you can achieve the rapid loading and unloading of goods. It greatly improves the factory's working efficiency and lowers labor number, to achieve more economic benefits.

- The ramp are made by all steel welded construction, with reliable strength, can be used for a long time without distortion.

- The steel diamond mesh on the ramp surface provides superior slip resistance, let the forklift have good climbing ability and maneuverability, even in rainy and snowy whether, it can still work properly.

- The length adjustable safety chains can connect the ramp with the vehicle conveniently and tightly.

- Manual hydraulic pump, no need electric power source can achieve the ramp's raising and lowering.

- The wheel chocks can prevent the ramp from moving when loading and unloading.